Aug 24, 2016

Aug 24, 2016

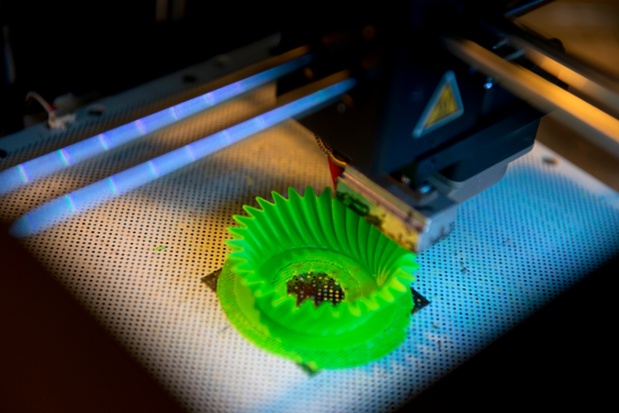

The two processes are similar — they both primarily produce parts and components from plastic, and they are both capable of high degrees of geometric complexity. However, there are important differences as well.

One of the more appealing aspects of 3D printing is the absence of steep initial costs. Because of its need for specially tooled dies, the creation of which is an expensive process, injection molding requires considerable initial costs. Though imposing at first, these startup costs are amortized over the lifespan of the die and the production run — in large volume injection molding projects, the startup costs are amortized over more individual parts, leading to a relatively low per-part cost.

Aside from its benefit in terms of initial costs, 3D printing has a number of limitations that the technology has yet to surmount, especially when compared to injection molding. There are still technical and software issues that cause costly and time consuming misprints; 3D printers are still quite rare, the printing process is notably slower than injection molding, and the produced parts are restricted in size.

Even 3D printing companies acknowledge these drawbacks. ODM WORK, a injection molding design manufacturer, conducted a study and found 3D printing mold to be cost effective only for very low volume runs of very small parts.

Mainland China Add: No.256 Xisanzhuang Street, Shijiazhuang City, Hebei Province, China

Home / Company / What Can We Do / Products / News / Contact Us / Sitemap Powered By