Jul 27, 2016

Jul 27, 2016

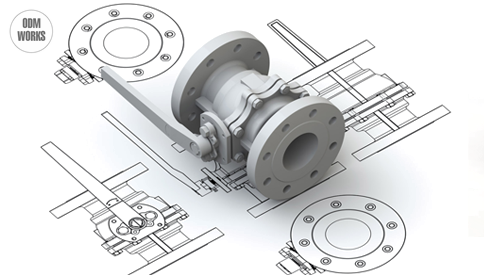

Before you can manufacture a plastic part you need to have a solid design in place. Once done, you can build an injection mold to meet the product specifications.

The role of the Design Engineer is critical in this process. They assess the part design and make modifications and recommendations based on key product requirements including product usage and function. The engineer will need to know:

² How will the part be used? Is it a standalone product or a component of a larger assembly?

² What are the dimensional and tensile requirements?

² Does the part need to withstand elements, pressure, chemicals?

A plastic injection mold design is built with these criteria in mind. Mold cavities, vents and gate placement will vary based not only on the part design but the type of resin as well. Taking all of these manufacturing factors into account is a challenging task and one that requires a strong knowledge base, not only of mold design but the injection molding process as well.

Mainland China Add: No.256 Xisanzhuang Street, Shijiazhuang City, Hebei Province, China

Home / Company / What Can We Do / Products / News / Contact Us / Sitemap Powered By